产品介绍产品图纸

本公司生产近30类,计140多种搅拌器,从最常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

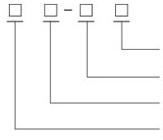

搅拌器型号标注方法:

材料代号

搅拌器轴孔径

搅拌器的外径,

搅拌器型式代号

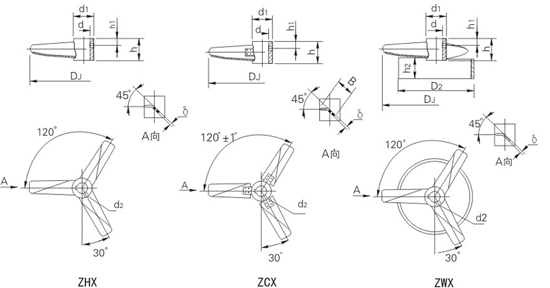

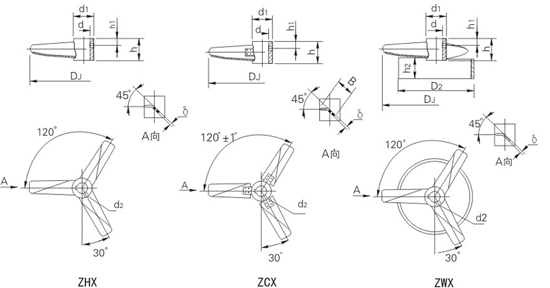

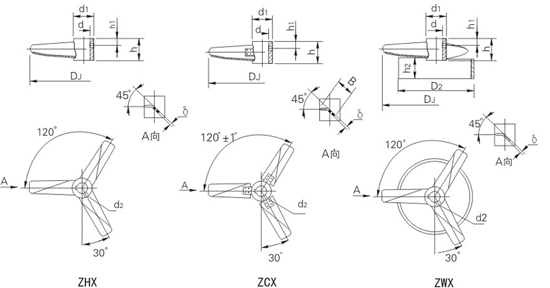

三窄叶整体旋桨式-ZHX、三窄叶可拆旋桨式-ZCX、三窄叶稳定环旋桨式-ZWX

三窄叶旋桨式搅拌器也是常用的旋桨式搅拌器,性能、应用都相似,相对于宽叶旋桨式,它的排出流量最小些,输入功率小些,常用介质粘度范围μ<10000cP,常用运转速度n=60-500rpm,常用尺寸DJ/D=0.2-0.5,B/DJ=0.2,常用左旋,可做成右旋。

三窄叶旋桨式搅拌器主要尺寸

DJ

d

d1

h

B

h1

d2

H2

D2

δ

重量(kg)(不锈钢/碳钢)

不锈钢/碳钢

ZHX

ZWX

ZCX

200

25

50

50

40

20

M6

30

135

3/4

0.97/0.98

1.272/1.380

1.57/1.58

220

30

60

60

44

20

M6

35

150

3/4

1.5/1.47

1.891/1.988

2.4/2.37

250

35

70

70

50

20

M8

38

170

4/6

2.25/230

2.891/3.256

3.48/3.53

280

35

70

70

56

20

M8

42

190

4/6

2.38/2.48

3.172/3.661

3.61/3.71

320

40

75

75

64

25

M8

50

215

6/8

3.38/3.5

4.981/5.621

5.06/5.18

360

40

75

75

72

25

M8

55

240

6/8

3.71/3.92

5.676/6.524

5.39/5.6

400

45

80

80

80

25

M10

60

270

8/10

5.09/5.36

8.306/9.355

6.8/7.07

450

50

85

85

90

25

M10

70

300

8/10

6.03/6.41

10.2/11.59

7.92/8.3

500

55

90

90

100

25

M12

75

335

8/10

7.2/7.63

12.19/13.83

10.62/11.05

560

60

100

100

112

25

M12

85

375

10/12

10.83/11.35

18.74/20.78

14.55/15.07

630

65

105

105

126

30

M12

95

420

10/12

13.19/13.91

23.09/25.72

17.06/17.78

710

70

110

110

142

30

M12

105

475

10/12

15.44/16.46

27.82/31.22

20.33/21.35

800

75

120

120

160

30

M12

120

535

12/14

22.5/23.68

41.62/45.87

27.75/28.93

900

80

130

130

180

30

M12

135

600

12/14

29.24/30.77

53.36/58.76

34.82/36.35

1000

85

140

140

200

30

M12

150

670

12/14

37.03/38.4

66.961/73.13

44.2/45.57

1120

90

150

150

224

30

M12

165

750

14/16

50.77/52.89

93.77/101.12

58.48/60.6

1250

100

160

160

250

30

M16

190

840

14/16

62.37/72.67

126.2/136.5

70.77/73.56

1400

110

180

180

280

30

M16

210

940

14/16

82.09/85.5

150.68/163.39

92.65/96.06

1600

120

190

190

320

30

M16

240

1070

16/18

114.77/119.23

216.7/233.2

125.84/130.3

1800

130

200

200

360

35

M16

270

1200

16/18

142.5/148.5

271.2/292.3

154.2/160.2

2000

140

210

210

400

35

M16

300

1340

16/18

173.59/182.60

333.2/361.1

185.8/194.9

2240

150

220

220

448

35

M18

335

1500

18/20

238.53/247/63

463.0/495.5

252.6/261.7

2500

160

240

240

500

40

M18

375

1670

18/20

287.68/305.16

567.4/614

302.8/320.3

备注:搅拌器内孔可根据用户要求制和,轮毂高度一般与内孔相一致。

本公司生产近30类,计140多种搅拌器,从最常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

搅拌器型号标注方法:

材料代号

搅拌器轴孔径

搅拌器的外径,

搅拌器型式代号

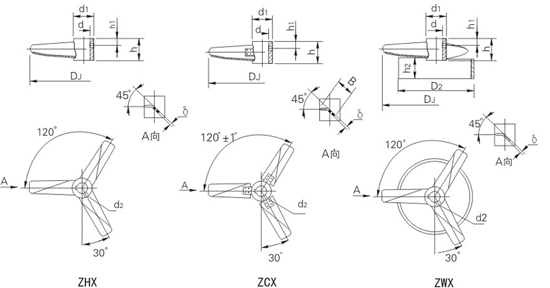

三窄叶整体旋桨式-ZHX、三窄叶可拆旋桨式-ZCX、三窄叶稳定环旋桨式-ZWX

三窄叶旋桨式搅拌器也是常用的旋桨式搅拌器,性能、应用都相似,相对于宽叶旋桨式,它的排出流量最小些,输入功率小些,常用介质粘度范围μ<10000cP,常用运转速度n=60-500rpm,常用尺寸DJ/D=0.2-0.5,B/DJ=0.2,常用左旋,可做成右旋。

三窄叶旋桨式搅拌器主要尺寸

DJ

d

d1

h

B

h1

d2

H2

D2

δ

重量(kg)(不锈钢/碳钢)

不锈钢/碳钢

ZHX

ZWX

ZCX

200

25

50

50

40

20

M6

30

135

3/4

0.97/0.98

1.272/1.380

1.57/1.58

220

30

60

60

44

20

M6

35

150

3/4

1.5/1.47

1.891/1.988

2.4/2.37

250

35

70

70

50

20

M8

38

170

4/6

2.25/230

2.891/3.256

3.48/3.53

280

35

70

70

56

20

M8

42

190

4/6

2.38/2.48

3.172/3.661

3.61/3.71

320

40

75

75

64

25

M8

50

215

6/8

3.38/3.5

4.981/5.621

5.06/5.18

360

40

75

75

72

25

M8

55

240

6/8

3.71/3.92

5.676/6.524

5.39/5.6

400

45

80

80

80

25

M10

60

270

8/10

5.09/5.36

8.306/9.355

6.8/7.07

450

50

85

85

90

25

M10

70

300

8/10

6.03/6.41

10.2/11.59

7.92/8.3

500

55

90

90

100

25

M12

75

335

8/10

7.2/7.63

12.19/13.83

10.62/11.05

560

60

100

100

112

25

M12

85

375

10/12

10.83/11.35

18.74/20.78

14.55/15.07

630

65

105

105

126

30

M12

95

420

10/12

13.19/13.91

23.09/25.72

17.06/17.78

710

70

110

110

142

30

M12

105

475

10/12

15.44/16.46

27.82/31.22

20.33/21.35

800

75

120

120

160

30

M12

120

535

12/14

22.5/23.68

41.62/45.87

27.75/28.93

900

80

130

130

180

30

M12

135

600

12/14

29.24/30.77

53.36/58.76

34.82/36.35

1000

85

140

140

200

30

M12

150

670

12/14

37.03/38.4

66.961/73.13

44.2/45.57

1120

90

150

150

224

30

M12

165

750

14/16

50.77/52.89

93.77/101.12

58.48/60.6

1250

100

160

160

250

30

M16

190

840

14/16

62.37/72.67

126.2/136.5

70.77/73.56

1400

110

180

180

280

30

M16

210

940

14/16

82.09/85.5

150.68/163.39

92.65/96.06

1600

120

190

190

320

30

M16

240

1070

16/18

114.77/119.23

216.7/233.2

125.84/130.3

1800

130

200

200

360

35

M16

270

1200

16/18

142.5/148.5

271.2/292.3

154.2/160.2

2000

140

210

210

400

35

M16

300

1340

16/18

173.59/182.60

333.2/361.1

185.8/194.9

2240

150

220

220

448

35

M18

335

1500

18/20

238.53/247/63

463.0/495.5

252.6/261.7

2500

160

240

240

500

40

M18

375

1670

18/20

287.68/305.16

567.4/614

302.8/320.3

备注:搅拌器内孔可根据用户要求制和,轮毂高度一般与内孔相一致。

本公司生产近30类,计140多种搅拌器,从最常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

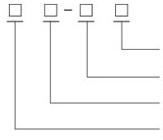

搅拌器型号标注方法:

|

|

| 材料代号 | |

| 搅拌器轴孔径 | |

| 搅拌器的外径, | |

| 搅拌器型式代号 |

三窄叶整体旋桨式-ZHX、三窄叶可拆旋桨式-ZCX、三窄叶稳定环旋桨式-ZWX

三窄叶旋桨式搅拌器也是常用的旋桨式搅拌器,性能、应用都相似,相对于宽叶旋桨式,它的排出流量最小些,输入功率小些,常用介质粘度范围μ<10000cP,常用运转速度n=60-500rpm,常用尺寸DJ/D=0.2-0.5,B/DJ=0.2,常用左旋,可做成右旋。

三窄叶旋桨式搅拌器主要尺寸

| DJ | d | d1 | h | B | h1 | d2 | H2 | D2 | δ | 重量(kg)(不锈钢/碳钢) | ||

| 不锈钢/碳钢 | ZHX | ZWX | ZCX | |||||||||

| 200 | 25 | 50 | 50 | 40 | 20 | M6 | 30 | 135 | 3/4 | 0.97/0.98 | 1.272/1.380 | 1.57/1.58 |

| 220 | 30 | 60 | 60 | 44 | 20 | M6 | 35 | 150 | 3/4 | 1.5/1.47 | 1.891/1.988 | 2.4/2.37 |

| 250 | 35 | 70 | 70 | 50 | 20 | M8 | 38 | 170 | 4/6 | 2.25/230 | 2.891/3.256 | 3.48/3.53 |

| 280 | 35 | 70 | 70 | 56 | 20 | M8 | 42 | 190 | 4/6 | 2.38/2.48 | 3.172/3.661 | 3.61/3.71 |

| 320 | 40 | 75 | 75 | 64 | 25 | M8 | 50 | 215 | 6/8 | 3.38/3.5 | 4.981/5.621 | 5.06/5.18 |

| 360 | 40 | 75 | 75 | 72 | 25 | M8 | 55 | 240 | 6/8 | 3.71/3.92 | 5.676/6.524 | 5.39/5.6 |

| 400 | 45 | 80 | 80 | 80 | 25 | M10 | 60 | 270 | 8/10 | 5.09/5.36 | 8.306/9.355 | 6.8/7.07 |

| 450 | 50 | 85 | 85 | 90 | 25 | M10 | 70 | 300 | 8/10 | 6.03/6.41 | 10.2/11.59 | 7.92/8.3 |

| 500 | 55 | 90 | 90 | 100 | 25 | M12 | 75 | 335 | 8/10 | 7.2/7.63 | 12.19/13.83 | 10.62/11.05 |

| 560 | 60 | 100 | 100 | 112 | 25 | M12 | 85 | 375 | 10/12 | 10.83/11.35 | 18.74/20.78 | 14.55/15.07 |

| 630 | 65 | 105 | 105 | 126 | 30 | M12 | 95 | 420 | 10/12 | 13.19/13.91 | 23.09/25.72 | 17.06/17.78 |

| 710 | 70 | 110 | 110 | 142 | 30 | M12 | 105 | 475 | 10/12 | 15.44/16.46 | 27.82/31.22 | 20.33/21.35 |

| 800 | 75 | 120 | 120 | 160 | 30 | M12 | 120 | 535 | 12/14 | 22.5/23.68 | 41.62/45.87 | 27.75/28.93 |

| 900 | 80 | 130 | 130 | 180 | 30 | M12 | 135 | 600 | 12/14 | 29.24/30.77 | 53.36/58.76 | 34.82/36.35 |

| 1000 | 85 | 140 | 140 | 200 | 30 | M12 | 150 | 670 | 12/14 | 37.03/38.4 | 66.961/73.13 | 44.2/45.57 |

| 1120 | 90 | 150 | 150 | 224 | 30 | M12 | 165 | 750 | 14/16 | 50.77/52.89 | 93.77/101.12 | 58.48/60.6 |

| 1250 | 100 | 160 | 160 | 250 | 30 | M16 | 190 | 840 | 14/16 | 62.37/72.67 | 126.2/136.5 | 70.77/73.56 |

| 1400 | 110 | 180 | 180 | 280 | 30 | M16 | 210 | 940 | 14/16 | 82.09/85.5 | 150.68/163.39 | 92.65/96.06 |

| 1600 | 120 | 190 | 190 | 320 | 30 | M16 | 240 | 1070 | 16/18 | 114.77/119.23 | 216.7/233.2 | 125.84/130.3 |

| 1800 | 130 | 200 | 200 | 360 | 35 | M16 | 270 | 1200 | 16/18 | 142.5/148.5 | 271.2/292.3 | 154.2/160.2 |

| 2000 | 140 | 210 | 210 | 400 | 35 | M16 | 300 | 1340 | 16/18 | 173.59/182.60 | 333.2/361.1 | 185.8/194.9 |

| 2240 | 150 | 220 | 220 | 448 | 35 | M18 | 335 | 1500 | 18/20 | 238.53/247/63 | 463.0/495.5 | 252.6/261.7 |

| 2500 | 160 | 240 | 240 | 500 | 40 | M18 | 375 | 1670 | 18/20 | 287.68/305.16 | 567.4/614 | 302.8/320.3 |

-

本公司生产近30类,计140多种搅拌器,从最常见的(包括已有的HB5标准,SB90标准各种搅拌器)到各种复杂形状或特殊用途的搅拌器。可按H/T2123-91标准的各种规格尺寸系列制造,也可根据用户生产工艺需求,代为设计制造各种特殊要求、特殊规格或特殊用途的搅拌器。

搅拌器型号标注方法:

|

|

| 材料代号 | |

| 搅拌器轴孔径 | |

| 搅拌器的外径, | |

| 搅拌器型式代号 |

三窄叶整体旋桨式-ZHX、三窄叶可拆旋桨式-ZCX、三窄叶稳定环旋桨式-ZWX

三窄叶旋桨式搅拌器也是常用的旋桨式搅拌器,性能、应用都相似,相对于宽叶旋桨式,它的排出流量最小些,输入功率小些,常用介质粘度范围μ<10000cP,常用运转速度n=60-500rpm,常用尺寸DJ/D=0.2-0.5,B/DJ=0.2,常用左旋,可做成右旋。

三窄叶旋桨式搅拌器主要尺寸

| DJ | d | d1 | h | B | h1 | d2 | H2 | D2 | δ | 重量(kg)(不锈钢/碳钢) | ||

| 不锈钢/碳钢 | ZHX | ZWX | ZCX | |||||||||

| 200 | 25 | 50 | 50 | 40 | 20 | M6 | 30 | 135 | 3/4 | 0.97/0.98 | 1.272/1.380 | 1.57/1.58 |

| 220 | 30 | 60 | 60 | 44 | 20 | M6 | 35 | 150 | 3/4 | 1.5/1.47 | 1.891/1.988 | 2.4/2.37 |

| 250 | 35 | 70 | 70 | 50 | 20 | M8 | 38 | 170 | 4/6 | 2.25/230 | 2.891/3.256 | 3.48/3.53 |

| 280 | 35 | 70 | 70 | 56 | 20 | M8 | 42 | 190 | 4/6 | 2.38/2.48 | 3.172/3.661 | 3.61/3.71 |

| 320 | 40 | 75 | 75 | 64 | 25 | M8 | 50 | 215 | 6/8 | 3.38/3.5 | 4.981/5.621 | 5.06/5.18 |

| 360 | 40 | 75 | 75 | 72 | 25 | M8 | 55 | 240 | 6/8 | 3.71/3.92 | 5.676/6.524 | 5.39/5.6 |

| 400 | 45 | 80 | 80 | 80 | 25 | M10 | 60 | 270 | 8/10 | 5.09/5.36 | 8.306/9.355 | 6.8/7.07 |

| 450 | 50 | 85 | 85 | 90 | 25 | M10 | 70 | 300 | 8/10 | 6.03/6.41 | 10.2/11.59 | 7.92/8.3 |

| 500 | 55 | 90 | 90 | 100 | 25 | M12 | 75 | 335 | 8/10 | 7.2/7.63 | 12.19/13.83 | 10.62/11.05 |

| 560 | 60 | 100 | 100 | 112 | 25 | M12 | 85 | 375 | 10/12 | 10.83/11.35 | 18.74/20.78 | 14.55/15.07 |

| 630 | 65 | 105 | 105 | 126 | 30 | M12 | 95 | 420 | 10/12 | 13.19/13.91 | 23.09/25.72 | 17.06/17.78 |

| 710 | 70 | 110 | 110 | 142 | 30 | M12 | 105 | 475 | 10/12 | 15.44/16.46 | 27.82/31.22 | 20.33/21.35 |

| 800 | 75 | 120 | 120 | 160 | 30 | M12 | 120 | 535 | 12/14 | 22.5/23.68 | 41.62/45.87 | 27.75/28.93 |

| 900 | 80 | 130 | 130 | 180 | 30 | M12 | 135 | 600 | 12/14 | 29.24/30.77 | 53.36/58.76 | 34.82/36.35 |

| 1000 | 85 | 140 | 140 | 200 | 30 | M12 | 150 | 670 | 12/14 | 37.03/38.4 | 66.961/73.13 | 44.2/45.57 |

| 1120 | 90 | 150 | 150 | 224 | 30 | M12 | 165 | 750 | 14/16 | 50.77/52.89 | 93.77/101.12 | 58.48/60.6 |

| 1250 | 100 | 160 | 160 | 250 | 30 | M16 | 190 | 840 | 14/16 | 62.37/72.67 | 126.2/136.5 | 70.77/73.56 |

| 1400 | 110 | 180 | 180 | 280 | 30 | M16 | 210 | 940 | 14/16 | 82.09/85.5 | 150.68/163.39 | 92.65/96.06 |

| 1600 | 120 | 190 | 190 | 320 | 30 | M16 | 240 | 1070 | 16/18 | 114.77/119.23 | 216.7/233.2 | 125.84/130.3 |

| 1800 | 130 | 200 | 200 | 360 | 35 | M16 | 270 | 1200 | 16/18 | 142.5/148.5 | 271.2/292.3 | 154.2/160.2 |

| 2000 | 140 | 210 | 210 | 400 | 35 | M16 | 300 | 1340 | 16/18 | 173.59/182.60 | 333.2/361.1 | 185.8/194.9 |

| 2240 | 150 | 220 | 220 | 448 | 35 | M18 | 335 | 1500 | 18/20 | 238.53/247/63 | 463.0/495.5 | 252.6/261.7 |

| 2500 | 160 | 240 | 240 | 500 | 40 | M18 | 375 | 1670 | 18/20 | 287.68/305.16 | 567.4/614 | 302.8/320.3 |